Technical Information

4. Sensor resistances on ceramic carrier

Temperature range of 70°C to +500°C. Special types from-196 °C to +500°C.

The platinum coating which is relevant for the temperature measurement is applied respectively according to one of the three following procedures:

- Screen printing

- evaporation

- sputtering.

With all three procedures the structuring of the resistance with the laser can take place.

In the first procedure the resistance can be also printed directly. In thin-film technology today structuring the resistance as from semiconductor technology known through optical lithography and sputtering cauterisation is accomplished.

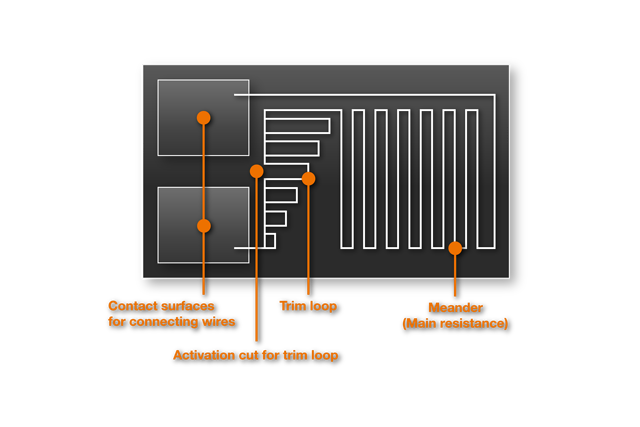

The fine adjustment always takes place with a laser. For this with the production of so-called trim or adjustment straining of different length (and thus different resistance) in is produced in the meander which is now activated depending on need by interruption of the prime conductor strip.

The meander surface is covered with melted glass. These resistances are oscillation resistant under normal installation conditions.

The hysteresis of these resistances behaves approximately the same as with the glass types. Sheath sensor resistances are only a few millimetres in size , are the most economical of all sensor resistances and yield very good measurement results.

Choose your language

Leave your number and we’ll call you back

Your direct contact to our team

GÜNTHER GmbH

Temperaturmesstechnik

Bauhofstraße 12

D-90571 Schwaig

info@guenther.eu

Tel. +49 (0)911 / 50 69 95-0

Fax +49 (0)911 / 50 69 95-55